Access Control Stickers & 'Tags

Access Control Stickers & 'Tags

Access Control Cards

Access Control Cards

Access Control Cards

Printed Plastic Cards

Printed Key Tags

Printed Gift Cards

Printed Hotel Cards

Printed Loyalty Cards

Custom Printed

Personalised Lanyards

Custom designed lanyards with choice of colour, attachment, and materials. All our lanyards come with a price match guarantee and free artwork design.

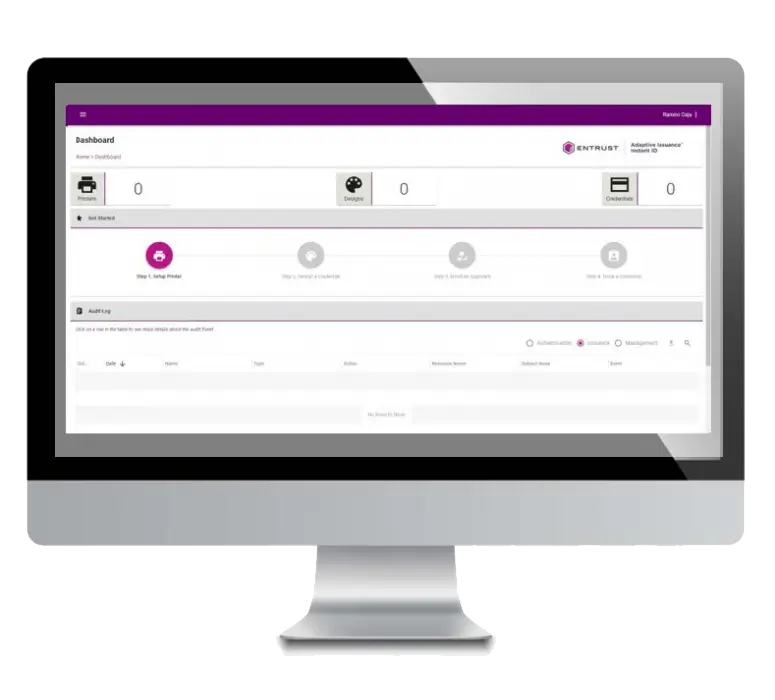

Entrust Instant ID Software is a complete solution for designing, printing, and managing ID credentials with speed and security.

Learn More

Easy-to-use ID card software for small businesses and schools. CardPresso offers templates, barcodes, and magnetic stripe support. Compatible with most card printers..

Learn More

Showing all 5 results

Access Control Stickers & 'Tags

Access Control Stickers & 'Tags

Access Control Cards

Access Control Cards

Access Control Cards

Smart 31s Card Printer

Smart 51S Printer

Smart 5D Printer

Zebra ZC100 Card Printer

Zebra ZXP7 Printer

Evolis Primacy Printer

Evolis Zenius Card Printer

Evolis Pebble Card Printer

Zebra Printers

Magicard Printers

Fargo Printers

Entrust Printers

Pointman Ribbons

Pointman Printers

Zebra ZC100 Ribbons

Zebra ZXP1 Ribbons

Zebra ZXP3 Ribbons

Zebra ZXP7 Ribbons

Zebra ZXP9 Ribbons

Entrust Sigma DS1 Ribbons

Entrust Sigma DS2 Ribbons

Entrust Sigma DS3 Ribbons

Card Holders

Paxton Cards

Mifare Cards

Pointman Ribbons

Magicard 300 Pro Bundle

Zebra ZC350 Ribbons

Lanyard

Lanyard Dublin

Lanyards & Card Holders

Magicard Pronto 100 Ribbons

Magicard 300 Ribbons

Magicard 600 Ribbons

Magicard Rio Pro 360 Ribbons

Magicard Ultima Ribbons

Evolis Badgy Ribbons

Evolis Primacy Ribbons

Datacard SD260 Ribbons

Evolis Zenius Ribbons

Datacard SD360 Ribbons

Datacard SD460 Ribbons

Smart 21 Ribbons

Smart 30 Ribbons

Smart 31 Ribbons

Smart 50 Ribbons

Smart 70 Ribbons

Smart 51 Ribbons

Datacard SP25 Ribbons

Fargo DTC4250 Ribbons

Card Printing Software

Easybadge Card Design Software

Custom RFID Cards

Printed Eco Cards

Asset Tags

Best ID Card Printers 2023

Printed Plastic ID Cards

PVC Card Printers

Printed Membership Cards

Gift Card Printing

Plastic Gift Cards

Gift Card Printers

Gift Card Technology

Gift Cards For Business

Gift Card Manufacturers

Print Plastic Gift Cards

Mifare Classic Cards

Mifare Desfire Cards

Paxton Access Readers

Paxton Net2 Cards

Paxton Net2 Proximity Cards

Paxton Net2 Fobs

Paxton Net2 Key Fobs

Paxton Fobs

Custom Plastic Gift Cards

Gift Card Printing

Gift Cards For Business

Loyalty Card Printing

Hotel Key Card Wallets

Gift Card Wallets

Plastic Card Wallets

Sustainable Hotel Keycards

Hotel Keycards

ID Card Printer

Plastic Card Printers

Card Printers

Library Membership Cards

Bone Tag Labels

You can see how this popup was set up in our step-by-step guide: https://wppopupmaker.com/guides/auto-opening-announcement-popups/