ID Card Printer – Smart 51D

Smart 51 ID Card Printer

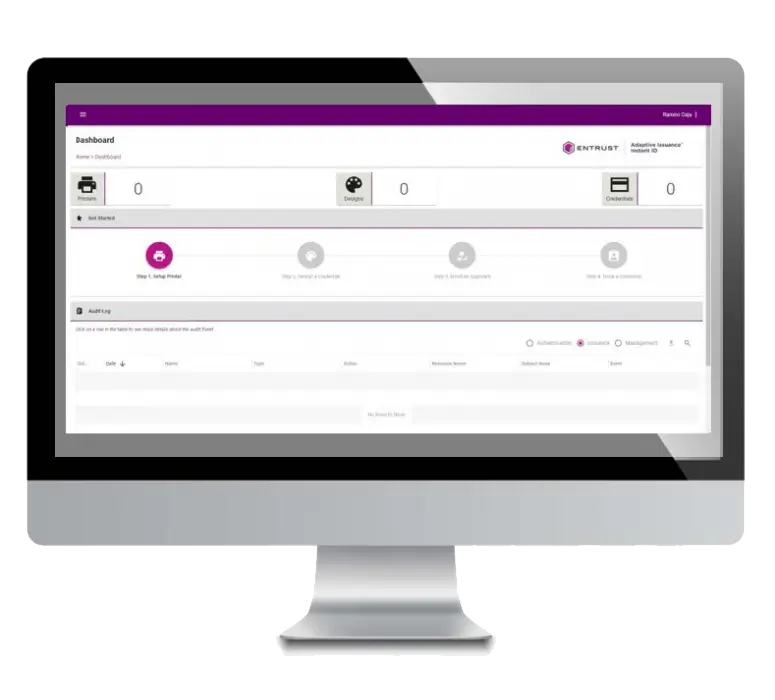

The Smart 51D is the latest addition to the hugely popular Smart range of ID Card Printers. This versatile machine is capable of printing a variety of ID cards with a range of different functions. Whether you need barcodes, magstripes or smart cards, this ID card printer has you covered – Smart indeed.

There has been explosive growth in the ID cards sector in recent years. Companies now use ID cards not just for identificaton, but for access control, purchases, rewards and more.

[x_icon type=”wrench” style=”font-size: 50px; color: #32679c; “]

Keep it simple

Printing has never been easier – with plug-n-play functionality and drag-n-drop design, creating your perfect ID cards has never been easier.

[x_icon type=”cogs” style=”font-size: 50px; color: #32679c; “]

Functionality

Print with no limits – this card printer is capable of handling all types of cards. Print, encode, laminate and more. Ideal for loyalty, membership and gift cards in addition to ID cards.

[x_icon type=”eur” style=”font-size: 50px; color: #32679c; “]

Save money

Supplying your staff with ID Cards doesnt have to break the bank. Printing your cards in-house can be a great way to save money and this low-cost id card printer is a great way to do it.

- Low-cost card printer

- Versatile

- 5-year warranty

Simplistic, affordable ID Card Printer

Talk to us today for advice on all things identification.

Related products

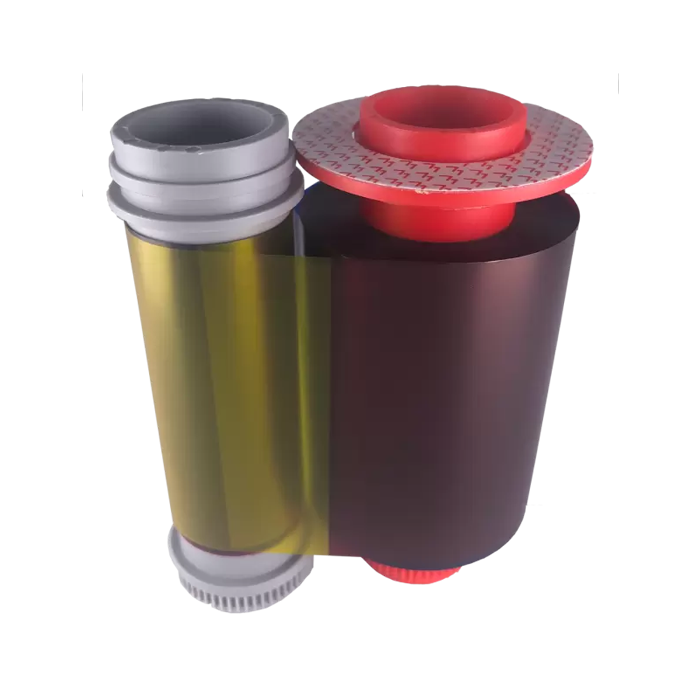

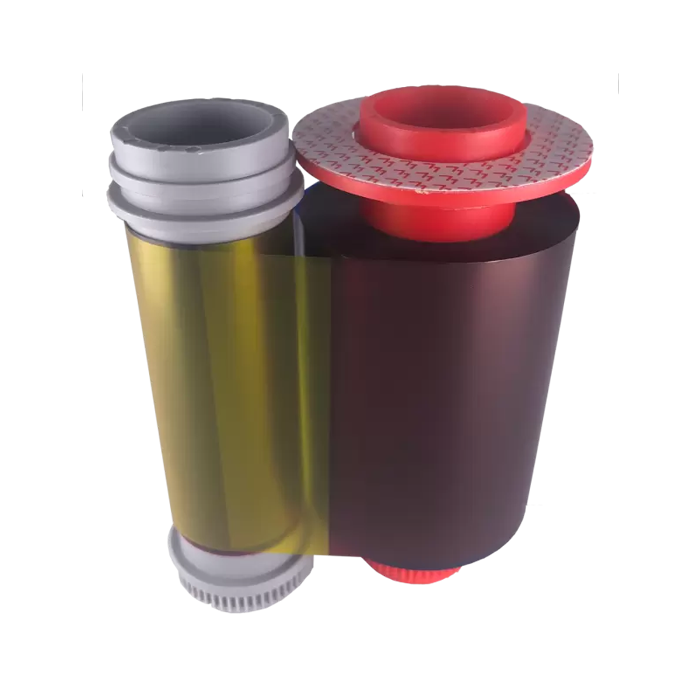

Fargo C30 Ribbons

Printer Ribbons

Matica MC210 Ribbons

Printer Ribbons

Matica MC310 Ribbons

Access Control Cards

Printer Ribbons

Printer Ribbons

Printer Ribbons

Uncategorized

ID Card Printers

Contactless Cards

Printer Ribbons

Uncategorized

Uncategorized

ID Card Printers